Silk fibre

Silk is protein fibre consisting of viscous fluid excreted from the glands of silk worm. When the silk worm is matured it consists of large number of glands. The liquid comes out from each gland in the form of fine stream. As soon as the excreted fluid comes in contact with air it is solidified in the form of fine filament. The filaments are wrapped in the oval shape due to spinning (circular movement) of the silk worm during the excretion of the fluid. When the formation of cocoon is completed the silk worm gets trapped into cocoon. The trapped silk worm is known as Pupa.

Varieties of silk

In India four varieties of silk are produced. These are

1. Mulberry silk

2. Tussar Silk

3. Erie silk

4. Muga Silk

The mulberry silk is known as cultivated silk, whereas, the other varieties are known as wild silk. Among these four varieties Mulberry silk is largely produced.

Mulberry silk has luxurious feel and shine. It is the most expensive fibre and known as queen fibre.

Silk Gum

The silk filament present on silk cocoons is coated with a gummy substance known as silk gum. Amount of silk gum present on silk filament depends on the silk variety. Among the four varieties of silk, mulberry silk is most popular and most commonly used by block printers for printing.

Pre-treatment processes for mulberry silk

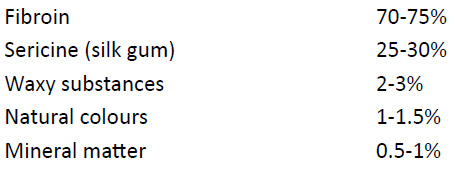

While considering the pre-treatment processes it is essential to consider the nature of impurities and their chemical nature. The composition of mulberry silk is

Added impurities like lubricants used during weaving and oil stains.

Before removal of gum silk filaments/fabric is brown, hard/ harsh and has no shine/lustre. Whereas, after removal of gum the filament/fabric becomes soft, acquires lustre. Naturally silk is cream in colour which is preferred in the market. Therefore, only pre-treatment required is for the removal of natural gums. If white silk is required, then bleaching with hydrogen peroxide is carried out.

Degumming of silk

The process of removal of natural gum from silk is known as degumming. Since presence of gum acts as a protective layer it also acts as natural sizing agent. Therefore, degumming of silk is carried out in fabric form after weaving. However, if the silk yarn is to be dyed, then degumming of silk in yarn form is carried out before yarn dyeing.

Degumming silk is usually carried out under mild alkaline conditions using soap. However, recently proteas enzymes are also suggested for silk degumming.

Degumming with soap

This is the most commonly used method for degumming. Traditionally olive oil soap known as Marseille soap is used. The alkalinity of soap and its detergency action not only hydrolyze sericine but also remove natural waxes and oil stains. Sometimes sodium bicarbonate or sodium carbonate (pH 10) is used along with soap.

The typical recipe and process conditions are:

• Marseille soap (olive oil soap) 25% owm

• Temperature 90oC -95oC

• Time 1-2 hours

Wash with hot and cold water to remove hydrolyzed gum.

Loss in weight 25-28% is expected depending on extent gum removal. If Marseille soap is not available, then normal soap with low alkalinity can be used. However, the process conditions must be standardized depending on the quality and alkalinity of soap used.

During soap degumming the natural waxes and oil stains are also removed.

Enzyme degumming

Protease enzymes act on proteins and convert them into water soluble amino acids. Trypsin (Serine protease) preferentially attacks silk gum. The degumming operation is carried out in two steps.

- Removal sericine (silk gum) using 1-2 g/l trypsin enzyme. The treatment is carried out at 50-60oC for 45- 60 minutes followed by hot water washing. In this step only gum is removed

- In step 2 natural waxes and oil stains are removed by treatment with 1 g/l soda ash at 80-90oC for 20 minutes followed by cold water washing twice.

Efficiency of degumming

Loss in weight is the common method to check the efficiency of degumming. The method consists of weighing the silk sample before degumming and after degumming. The difference in weight is expressed in terms of % gum removal. The extent of gum removal should be to an extent of 80% for satisfactory degumming. However, in some cases partial degumming of silk is also carried out. Therefore the extent of gum removal would depend on the market requirements.

Leave a Reply