1. Test fabric for absorbency

Purpose

To ensure that the fabric can absorb water easily. Printing pastes are composed mainly of water and hence if the fabric has a high absorbency the paste will fix better. Good absorbency is also one indicator (but not the only one) that the preparatory process for printing (RFD) has been done well. Prior to printing, all material should be tested for absorbency. Apparatus: None.

Testing procedure

Absorbency can be checked by dropping a single droplet of water on the fabric and visually observing its absorbency. A fabric with high absorbency will immediately absorb the drop of water, which should spread uniformly in all directions. In the case of low absorbency it may take a few seconds. (There may also be cases where the fabric has been treated, in which case the drop of water may not spread at all).

2. Test fabric for its pH level (level of acidity/ alkalinity)

Purpose

To ensure fabric being printed on has the right level of acidity/ alkalinity which would affect the colour the printing paste leaves behind. Ideally the pH should be between 6.5 and 7.

Testing procedure #1 (only if the fabric being tested is white or off-white)

On the fabric apply a drop of the pH Universal Indicator Solution (also referred to as the Litmus Solution). Match the colour of the solution on the fabric against the possible shades that the solution can take (which are provided by the solution manufacturer). The colour will be reflective of the pH of the fabric, which should be in the range of 6.5 to 7.

The Universal Indicator Solution is widely available and can be kept in stock.

Testing procedure #2 (applicable for all fabrics)

In this alternate approach the fabric is boiled in water to extract the acid/ alkaline source, which is then measured.

This can be carried out in the following steps:

- Take distilled water (pH=7) in a utensil and bring it to boil. Distilled water can either (a) be bought locally (several car battery shops carry distilled water); or (b) made in house with a distiller (that can be bought at a lab equipment seller).

- Take a swatch of 10 inches square of the fabric and put it in the boiling water for20 minutes.

- Remove the swatch and let the boiled water cool to room temperature.

- Measure the pH of the water with pH paper and record it. That pH should stay 7; and any change is on account of the fabric. The pH paper (also called universal indicator paper) can be bought at most shops selling laboratory equipment and auxiliaries.

What if the pH of the fabric is outside the desired range?

If the pH of the fabric is either more acidic or more alkaline than it is supposed to be, then the pretreatment of the fabric or its storage need to be looked into. A high/ low pH will cause colour variations in the printed fabric.

It is advisable to wash the fabric in plain water and remove the excess acidity/ alkalinity prior to printing.

Test fabric for its weight (Mass, GSM)

Purpose

To ensure fabric being worked on or being sent is as per specifications. It helps ensure that the chemical and dye application is appropriate.

GSM (Grams per Square Meter) of all incoming material should be verified.

Apparatus: Calibrated weighing machine

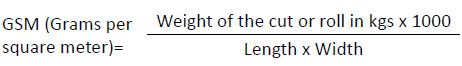

Testing procedure #1: For piece, cut or roll

The full piece, cut or roll should be weighed on a calibrated scale, accurate to 0.25%. The length and width of the fabric should then be measured, and the mass should then be reported in grams per square meter to the nearest 2 g.

3. Testing procedure #2: For a small sample piece

From the fabric, a specimen should be cut to have an area of at least 100 sq. cm (or a number of specimen not less than 10 sq. cm. each and having a total area of at least 100 sq. cm.). This should then be weighed on a calibrated scale accurate to 0.25%. The length and width of the fabric should then be measured, and the mass should then be reported in grams per square meter to the nearest 2 g.

It should be noted that this test method is intended for use when a small sample of fabric is available to the laboratory for test. The result is considered to be applicable to the sample, but not to the piece or lot of goods from which the sample was taken unless the number of samples and method of sampling are specified and agreed upon by those concerned. If this is done, each sample should be tested in accordance with above method and the results averaged to obtain the average mass in grams per square meter.

4. Test fabric for shrinkage to washing

Purpose

To determine the ability of the fabric to resist shrinkage

References

ISO 6330 – Standard Test Methods for Fabrics

Apparatus

Washing machine and shrinkage template with scale

Procedure

Three specimens, 50 cm x 50 cm should be accurately measured and marked with shrinkage template26 in each direction to the nearest 0.5 mm. The specimen should then be soaked for 30 minutes in distilled water at room temperature, or machine washed as per the buyer’s requirement and removed and dried at less than 80 degC till it is completely dry.

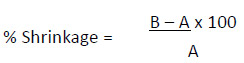

The specimen should then be conditioned at the standard conditions of 20±2 degC, and 65±4% humidity for a minimum of 4 hours prior to measuring. The percent shrinkage in each direction shall be calculated using the following formula:

Where A = Length before test. B = Length after test. (-) sign shows shrinkage and (+) sign shows elongation in the fabric.

Testing any dyes and pigments procured for consistency/ quality

Purpose

To test and affirm that a new batch of dyes performs like it is supposed to; and in several cases performs like the last set of dyes.

Procedure

Dyes and pigments can be tested for performance test by applying required percentage on a swatch of fabric and evaluating for strength/ tone. The swatch should compared with the swatch that was prepared the last time that dye/ pigment was bought. Inconsistencies should immediately be brought to the notice of the manufacturers or seller.

26 A shrinkage template is a calibrated template available in 3 sizes but 50 cm x 50 cm widely used.

Leave a Reply