Various tribes or groups of people, the world over have their own symbolism. A specific colour; a particular kind of embroidery, a distinguished style of jewellery or the patterning on their garments helps us recognize them. This gives them their own unique identity. Even today we find communities in remote areas in India as well as other parts of the world, where a specific style of printing in precisely the same design and colour is worn by every individual of the same group.

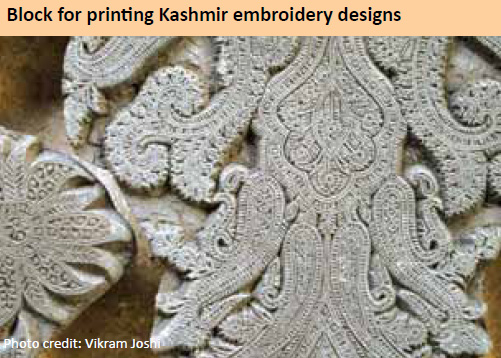

Today India has many major printing centres with their own block making skills and history. Wood blocks are largely used for printing fabrics for costumes, floor coverings, bedspreads and sometimes even wall hangings or prayer rugs. Blocks are also used to transfer designs, which were used by the embroiderer as a guideline for embroidery; for example in – Chikankaari of Lucknow, Kashmiri shawls and Pheran; embroidered yolks in Rajasthan and Gujarat.9 Another technique where blocks are used to print the basic design before the real work started was tie and dye or baandhani from Kutch.

(Courtesy: private collection of Vikram Joshi)

Customs and practices associated with blocks

A block printing unit which has been running from generations will probably have thousands of blocks. Blocks are rarely thrown away. One of the reasons for keeping the blocks is that there are many designs which come back in fashion after a few years.

Another way of documenting the design of each block is to take a “Parat”, a precise impression of the fresh block taken by the block printer before printing starts. This remains in the records, as a future reference for the block maker.

The more organized printers have books, which will have a chaap, a print of each existing block in the unit. A particular number is assigned to each block and the same is mentioned on the print in the reference book. This catalogue is supposed to help one in finding the blocks. The catalogues are very useful for designers or business establishments, who want to work in these units. Another way of cataloguing- that we sometimes come across is filling different styles or collections of blocks in small cardboard boxes, and then sticking the block designs outside the box. These prints also mention the number assigned to the block.

Old blocks are never sold by traditional printing families. Sometimes if the blocks are too old and completely useless then they might be taken to the river and given away in a proper ceremony, like the ashes of the dead is given to the rivers. This shows how alive the blocks are to the printers.

Most printers usually have memorized the design of each block in their mind, and the moment you describe one, they will not look at the catalogue, but just tell you where to find it. They would tell you exactly on which shelf, in which direction, or under which table one must be able to find it. Ironically many of them have never been to school, or if they have been there it was so brief that it is not worth mentioning. But that does not change the fact that without using a ruler they can make the straightest line that an artist can make after being trained in an art school. Their eyes and hands are so well trained you can actually see them measuring each border by the movements of the eyes.

While walking through various block printing units and getting work done there, one gets more and more familiar with the customs, which are quietly followed. One slowly learns about the strict training and the kind of education that the printers go through during the course of action. When a new person comes to learn how one of the old masters or a well trained person will take the pupil – Shaagird under his guidance. The master himself usually will be a practicing printer and very respectful towards the need of the establishment for whom they both work. He will not only take good care of the new pupil, but teach him from step one. The new comer watches the movements of the hand, while doing all the side jobs for the master or the Guru – the teacher so that he is not disturbed during the printing process. The ultimate goal is to do maximum good quality production within the limited time frame given to them as a team, while keeping a balance of the hierarchy.

Leave a Reply